Visits of Two Catamarans for Sale in Spain

Dean Jag 530 wreck intrigues us ([see the article: The Search for the Ideal Boat for Refit to Electric Propulsion]({{< ref "20200815" >}})) and …

We are now the owners of a power catamaran, one that has no engines. It is therefore necessary to choose the new electric propulsion system and the batteries. We have just signed the purchase of a system of two 50 kW engines under 96V and 72 kWh of batteries. Before sharing the technical details of the system we have selected, I will explain how we have researched and reached this decision: how much power is necessary for our needs and then which suppliers were considered and consulted.

Dean Catamarans had powered the Jag 530 with two Vetus DTA 67 engines of 286 HP each. These engines allowed a cruising speed of 15 knots and a top speed of 20 knots. Since we are switching to electric propulsion, we will use kW as the unit of power and not in HP. The original engines therefore had a power rating of 210 kW each.

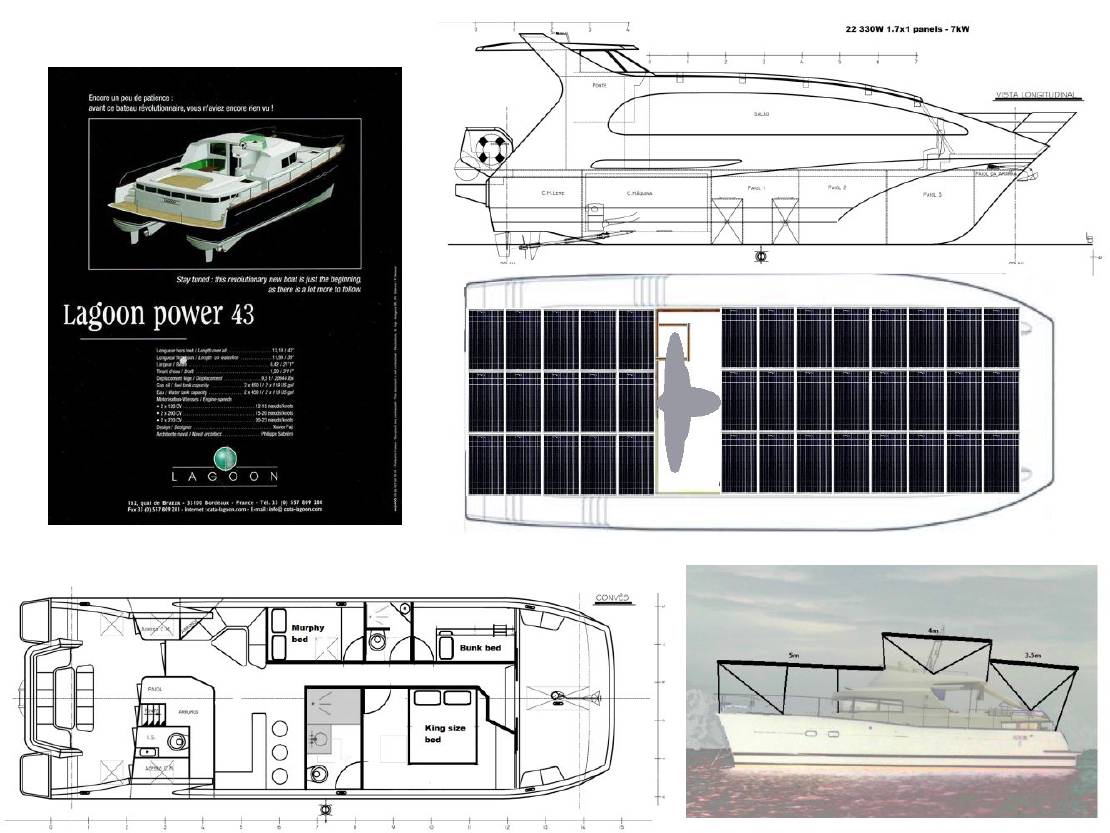

A quick estimate of the solar energy that we can expect to produce with the available surface gives us around 15 kWp. kWp means “kilowatt peak”, or the energy that the solar panels can produce under an ideal solar situation. Realistically, we can expect to generate 5 to 6 times this “peak rating” per day, or between 75 kWh and 90 kWh for a perfectly sunny summer day. It is therefore obvious that it would be completely useless to install a 400 kW propulsion, because the energy generated in one day would be consumed in less than 15 minutes. In short, relying on the old engine power rating is not the right approach.

We must turn the problem around and decide what cruising speed we consider and what top speed we wish to achieve. A cruising speed of 4 to 5 knots seems adequate because we really want to avoid having to use any energy other than solar and we are determined to live slowly, in harmony with our environment. Most sailing boats generally sail at speeds of 4 to 6 knots. To give a concrete example, let’s take the distance from Nice to Calvi for a crossing to Corsica. It takes about 22 hours to cover the 100 nautical miles in a straight line at this average speed, or a little less than a day and a night, which is usual for sailors. For the choice of top speed, being close to 10 knots would be desirable, either to be able to reach shelter quickly if the weather turns bad, or to be able to move against a strong current in a pass, or other difficult situation. In any case, we must be aware that the top speed will not be sustainable for long. Maybe 30 minutes to 60 minutes maximum.

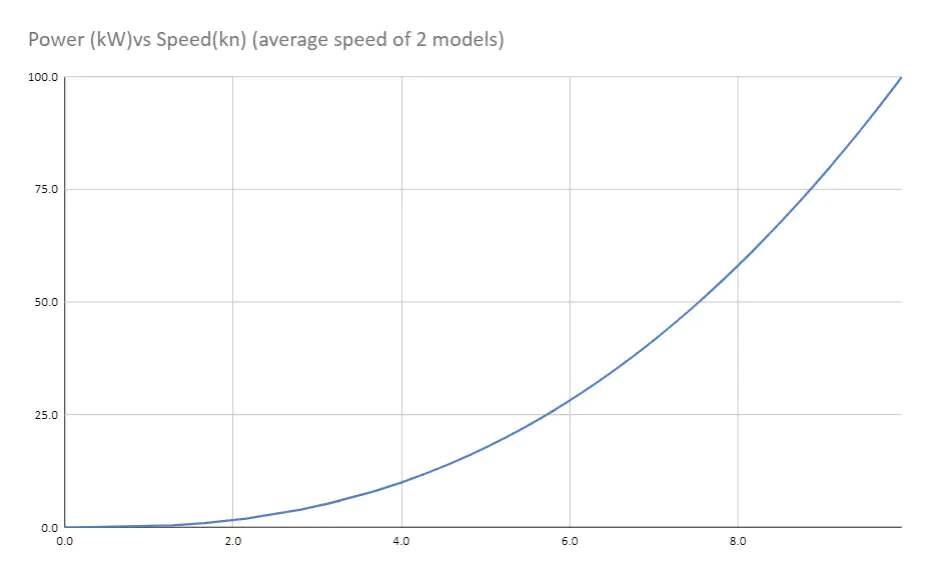

Once we have defined our desired cruise and top speeds, we can use formulas for displacement hulls (our catamaran will never be able to reach planning with her 20 tons). Two formulas are useful for this: Keith’s formula and Crouch’s formula. Keith’s formula takes into account the weight and the length at the waterline of the boat, while Crouch only uses the weight. They give results with significant differences, so for our estimates, we decide to take the average between the two.

Crouch’s Formula: Speed = Constant / sqrt(Weight/Power) with Speed in knots, Weight in pounds and Power in HPs. The Constant varies with the type of hull; for our displacement hull, a value between 150 and 190 seems appropriate.

Keith’s Formula: Speed = 5280/6080 x sqrt(Length) x 1.4 x exp((log(Power x 1000 / Weight)) / 3 x 2.30258) with Speed in knots, Weight in pounds, Power in HPs and Length in feet

There are other formulas very close to Keith’s: the Wyman’s and Geer’s formulas. They all have the same form, but with different coefficients.

This average between the Keith’s and Crouch’s formulas gives us that to move at 4 knots, we would need 10 kW, at 5 knots 18 kW and at 10 knots 100 kW.

These estimates lead us to decide that 2 motors capable of delivering 50 kW peak each would be sufficient.

Another way to get good advice is to ask boat building professionals what power they recommend, keeping in mind that we want to move slowly, like a sailboat and not like a fast motorboat.

Our boatyard recommends a motorization of at least 5 HP per ton of boat. They use this rule to size a diesel engine to a sailboat. This is 3.8 kW per ton, so 76 kW for our 20 ton catamaran.

While searching for electric motor vendors, we found that Fischer Panda recommends 2.5 kW per ton, or 50 kW for our 20 ton catamaran.

Another data source, on the website Multihull.de suggests 1 kW per 300 kg, or 3.33 kW per ton, or 66.6 kW for our catamaran.

All these data sources confirm that our calculations to have 100 kW peak with our 2 engines make sense.

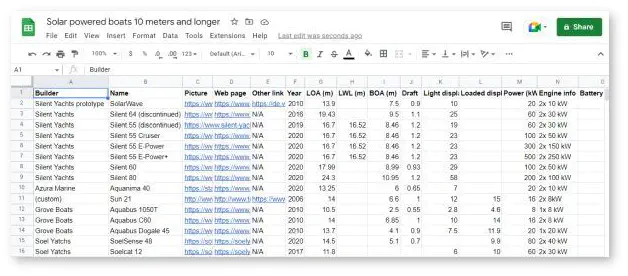

Yet another way to validate our calculations is to compare our results with what electric boat builders have done already. I have collected all the information I could find on electric and solar powered boats in a document for the past couple of years and I can filter for catamarans of a weight close to our Jag 530 and see what electric motor power they have installed.

I summarize in the table below the interesting information for this post:

| Shipyard | Model | Year | Weight | Power | kW per ton |

|---|---|---|---|---|---|

| Solar Yachts | Silent 64 | 2016 | 25 | 2x 30 kW | 2.4 |

| Solar Yachts | Silent 55 | 2019 | 19 | 2x 30 kW | 3.2 |

| Solar Yachts | Silent 55 Cruiser | 2020 | 23 | 2x 50 kW | 4.3 |

| Solar Yachts | Silent 55 E-Power | 2020 | 23 | 2x 150 kW | 13.0 |

| Solar Yachts | Silent 55 E-Power+ | 2020 | 23 | 2x 250 kW | 21.7 |

| Azura Marine | Aquanima 40 | 2020 | 7 | 2x 10 kW | 2.8 |

| (custom) | Sun 21 | 2006 | 12 | 2x 8 kW | 2.0 |

| Soel Yatchs | Soelcat 12 | 2017 | 10 | 2x 40 kW | 8.0 |

| Soel Yatchs | SoelSense 48 | 2020 | 10 | 2x 40 kW | 8.0 |

| metaltec naval | ECOCAT 12m | 2020 | 12 | 2x 20 kW | 3.33 |

| Aquila (custom) | 44 - First Edition | 2019 | 18 | 2x 50kW | 5.6 |

Seeing these numbers reassures us about our decision to re-power with 2x 50 kW, in line with what has been done before, especially for catamarans built up to a year ago. In 2020, new models have started to use more powerful engines, but most are hybrid electric catamarans with large diesel generators onboard to provide the energy necessary to power the motors.

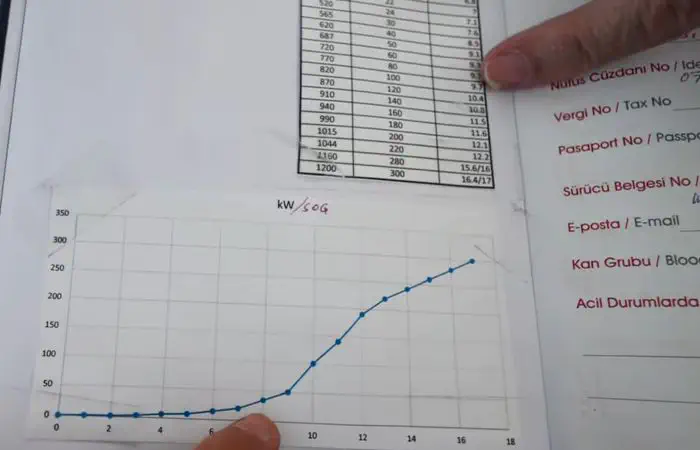

On this speed/power curve of the new Silent Yacht Silent 55 Cruiser, we notice that the power range from 100 kW to 300 kW pushes the catamaran from 10 to 17 knots.

Now that we have defined the desired power for our propulsion system, we must decide another important parameter: the supply voltage that we will use for propulsion.

The Dean Catamarans Jag 530, like most boats of this size, had battery banks for the 12V circuit for the navigation electronics and safety equipment and a large 24V bank for everything else. To get 100 kW from a 24V bank, it would be necessary to draw a current of more than 4000A. This is technically impossible.

12V and 24V do not present a risk of electrocution for humans, even in wet environments. 48V is considered the high limit of non-hazardous voltage. We must be cautious with electric systems above 48V, for the installation, operation and maintenance of the electrical system.

The 4 voltages commonly used by propulsion motor and controller manufacturers are the following, followed by the current required for 100kW at this voltage:

The lower the current, the smaller and lighter the electrical cables are, but we increase the danger due the high voltage required.

Another factor comes into play: the choice of the voltage of the propulsion system dictates the choice of the voltage of the battery bank. With high currents, we cannot rely on DC-DC conversion for 100kW of power (for example to step up the voltage from 48V to 400V for the motors). A DC-DC conversion loses about 5% of the energy in heat and these converters are prohibitively expensive.

We will therefore need to find a several electronic components that can operate at the voltage of the high voltage battery bank:

At 48V, the offer is plentiful. Above that voltage, components are more difficult to find. A quick search shows that there are some MPPT chargers for 96V batteries, as well as inverters. At 144V it is more difficult and at 400V+, it is extremely complex to find anything, because it is well above the voltage of the do-it-yourself projects.

In conclusion, there are two voltages that are suitable for our project: a 48V propulsion (ideal) and a 96V propulsion (acceptable, with the advantage of currents reduced by half in the cables compared to 48V).

The rotation speed of a propeller of a sailing boat is generally between 850 and 1650 rotations per minute (RPM). We have the space to install propellers up to 1 meter in diameter under our catamaran so it would be rather interesting to have a low rotation speed with large propellers. This would minimize noise and vibrations, avoid the risk of cavitation, etc.

Diesel engines use a gearbox to reduce the rotation speed of the propeller shaft to around 1000 revolutions per minute (RPM). For our project, the objective is to avoid a mechanical speed reduction gearbox, which would add additional cost, weight, noise, maintenance, etc. We are therefore preferably looking for a supplier who has electric motors we could put straight on the propeller shaft, with maximum power at a speed close to 1000 RPM.

Model EasyBox HV | Power 50 kW | Voltage 360V | Direct transmission Yes

Pros:

Cons:

Model ACX30 | Power 30 kW | Voltage 48V | Direct Transmission Yes

Pros:

Cons:

Model ISCAD V50 | Power 50 kW | Voltage 48 V | Direct Transmission No

Pros:

Cons:

Model Gear motors for extra heavy duty | Power 50 kW | Voltag 144 V | Direct Transmission No

Pros:

Cons:

Model Electric Propulsion System | Power 23 kW | Voltage 96V | Direct Transmission Yes

Pros:

Cons:

Model WA WAz 30 AC | Power 30 kW | Voltage 144V | Direct Transmission No

Pros:

Cons:

Model DriveMaster 45W | Power 45 kW | Voltage 144V | Direct Transmission Yes

Pros:

Cons:

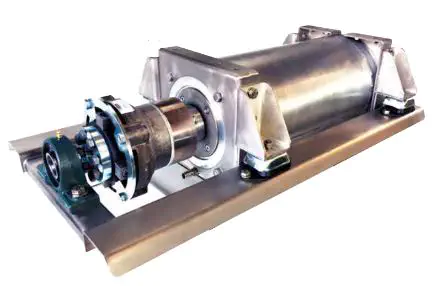

Model 50IB | Power 50 kW | Voltage 96V | Direct Transmission Yes

Pros:

Cons:

Model 35 WGH | Power 35 kW | Voltage 144V | Direct Transmission Yes

Pros:

Cons:

Model QuietTorque 30 LC | Power 30 kW | Voltage 48 V | Direct Transmission Yes

Pros:

Cons:

Model MA300 | Power 30 kW | Voltage 96 V | Direct Transmission Yes

Cons:

Model EP-100 | Power 42 kW | Voltage 144 V | Direct Transmission Yes

Pros:

Cons:

The selection of our electric propulsion supplier has evolved a lot over the last 2 months. I was very interested in working with Molabo, not only to help an early stage startup, but for the qualities of their engine too. Unfortunately, our last discussions showed that it is necessary to use a gearbox due to the high RPMs of the motor. The additional cost is acceptable, at about 600 Euros per motor, but the goal is to have the motor on the propeller shaft, so I abandoned their proposal. Their solution is very interesting for fast and light boats, not necessarily for our slow and heavy boat.

I then decided to work with Bell Marine. Their product is solid and although their 45 kW engine works at 144V, they can provide MPPT chargers from the solar panels for the 144V batteries (AERL Coolmax MPPT chargers) and offer a 144V inverter too. Buying a complete system from them solves my biggest problem with 144V. However, after a first contact with Bell Marine in the Netherlands, they redirected me to their dealer in Spain, because they do not sell directly to customers. The few contacts with the reseller were not fruitful. No problem sending multi-page PDFs with images and pricing, but no technical expertise on the requested products and a slow response in getting each answer. My confidence in having a technical partner able to ensure that all the components will be well chosen, well configured, has disappeared.

I finally went back to my list of possible suppliers and I contacted a German entrepreneur, integrator of electric propulsion systems for boats and land vehicles, RiPower GmbH. The first attempt at a telephone call was not successful, because the owner does not speak English and my German is too limited to discuss the project. We therefore agreed to communicate by emails in English and he will use Google Translate. After detailing the project, providing specifications and photos of the catamaran, RiPower prepared a commercial proposal including the 50 kW 96V motors, batteries, throttles, a 220V charger, propellers including the calculations, cables harness. An additional benefit is that the RiPower workshop is 1h30 drive from our home in Berlin and we will be able to go onsite if needed.

The order has been placed with RiPower GmbH. We can’t wait for our motors and batteries to arrive in Alicante!

Dean Jag 530 wreck intrigues us ([see the article: The Search for the Ideal Boat for Refit to Electric Propulsion]({{< ref "20200815" >}})) and …

Here is a summary of my research, readings and thoughts on the type of boat that could serve as a starting point for our project. I have spent time …