Refit Project Update - Q1 2021

The refit of the Escargot has begun! After four months of hard work by the shipyard workers, we're excited to share our first major update. Our …

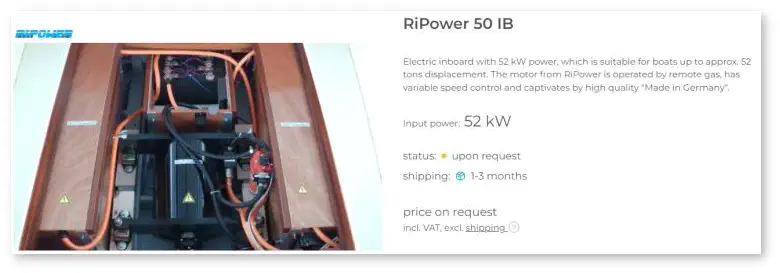

There have been many changes to our propulsion and energy storage system over the last 3 months. We exchanged regular emails with the owner of RiPower to further define the project. At the beginning of February, he shared with us that he had underestimated the size of our catamaran (ouch…!) and thought the electric motor model he usually used for his 50IB system would not be suitable. Indeed, like many motors for electric vehicles, this one reaches its maximum power at a high rotation speed, around 4000 RPM. On our catamaran, this motor would therefore be used in a power range that is much too low, unless we added a gearbox to reduce the rotation speed, but it is not what we want as detailed in the post on our research on electric propulsion.

RiPower suggests we use a different motor. He found a demonstration system from the manufacturer FIMEA consisting of 2 N80 motors of 50 kW each. The motors have been lightly used for tests and demonstrations, but being asynchronous motors they have no parts that wear out. We accept his proposal as it meets our requirement of avoiding adding a gearbox.

FIMEA is an Italian company manufacturing industrial three-phase asynchronous motors and they also have a product line for electric vehicles, especially suitable for boats thanks to their IP65 rating protection against dust and water. The motors won’t operate submerged, but they can be be heavily sprayed, which is perfect when installed on a boat.

At the end of February, RiPower informs us of another change, which requires additional cost. The thrust bearings normally included are not large enough for the thrust that the propeller shaft will transmit to the boat. They also need additional protection from the Mediterranean climate according to his messages translated by Google Translate. These bearings are very important, because they transmit the thrust of the propeller to the hull of the boat, instead of pushing or pulling on the electric motor shaft, which would not support this force. New Python Drive PD-T bearings for our 50mm shafts are now ordered, at an additional cost though.

For the past 2 months, the discussions with RiPower have been about the BMS for the Lithium battery. The BMS is the electronic system managing the batteries, monitoring the temperature of the elements in the battery and ensuring that these elements all have a relatively close voltage. The BMS communicates with the battery charger to know when to stop the charge. I will have to find or build an interface so that the BMS can also cut off the solar chargers in the event of overheating of the battery elements.

The BMS selected when we placed the order of our complete system is out of stock, again due to the ongoing COVID-19 pandemic. We first consider replacing it the REC BMS. The REC product range seems solid and has a good reputation. In our configuration, with four 96V batteries, we would require two REC Q BMS 16S and one REC BMS Master Unit 9M in each battery. I had studied the documentation of this system and I liked it because of the quality of its literature, the ease of future expansions with for instance the connectivity to the solar chargers and its reputation. On the other hand, RiPower announced an increase of 3000 Euros to switch to the REC BMS solution. This hurts to see the budget increase again, but it is critical to have a trusted system that ensures the good health of the batteries and even more their operational safety. Again, we approve the cost increase.

A few days ago, bad surprise, it seems that REC BMS cannot be installed with a CAN bus as long as necessary in our catamaran. The bus must indeed connect the 4 batteries, the charger and the display located in the cockpit. We need about 30 meters of bus and RiPower believes that it is too long. He decides to order a BMS system from Boostech, instead of the REC that I had just approved. I have not yet read everything about this other product. It is manufactured by a German company and its documentation is only available in German. Their product seems to be widely used by enthusiasts who assemble their own batteries for all sorts of electric vehicles. The product reviews seem good and RiPower is convinced that it is the right solution for our project. We follow along and approve this decision. There is one thing bothering me with the Boostech system though: the 4 batteries are connected to a single control system, the Master Unit. If this system fails, there is no longer any monitoring or balancing of the cells of the 4 batteries. To overcome this problem, I decide to order a second Boostech BMS Master Unit, which will be already configured and ready to replace the other one if it ever became defective. Redundancy is critical when you are at sea and you have a problem with an electronic system.

RiPower lets us know that the FIMEA motors should be shipped to him on May 15th. Things are progressing slowly. However, I have come to realize in recent months that working with a very small company like RiPower for a project of this size is ambitious. I appreciate being able to communicate directly with the entrepreneur and to be included in the exploration of alternative solutions, but all these rapid changes are problematic, increase the budget and show that the project had been initially underestimated by the supplier.

The refit of the Escargot has begun! After four months of hard work by the shipyard workers, we're excited to share our first major update. Our …

We are now the owners of a power catamaran, one that has no engines. It is therefore necessary to choose the new electric propulsion system and the …